News RSS

PlasmaSens torch height contol test

PlasmaSens torch height contol test

There is very simple way to test your PlasmaSens THC controller with our PoKeys application. Just connect the PlasmaSens to PoKeys57CNC and follow these steps for torch height control test.

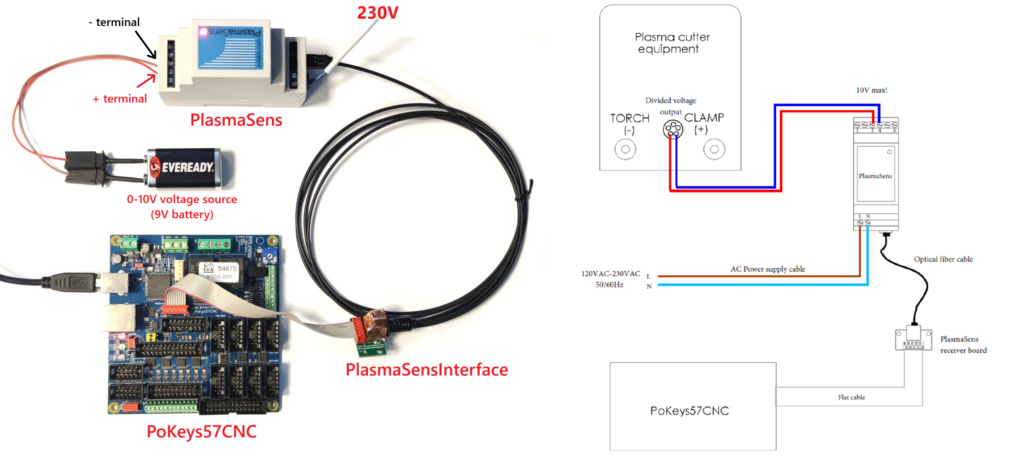

Connecting the PlasmaSens to the PoKeys57CNC

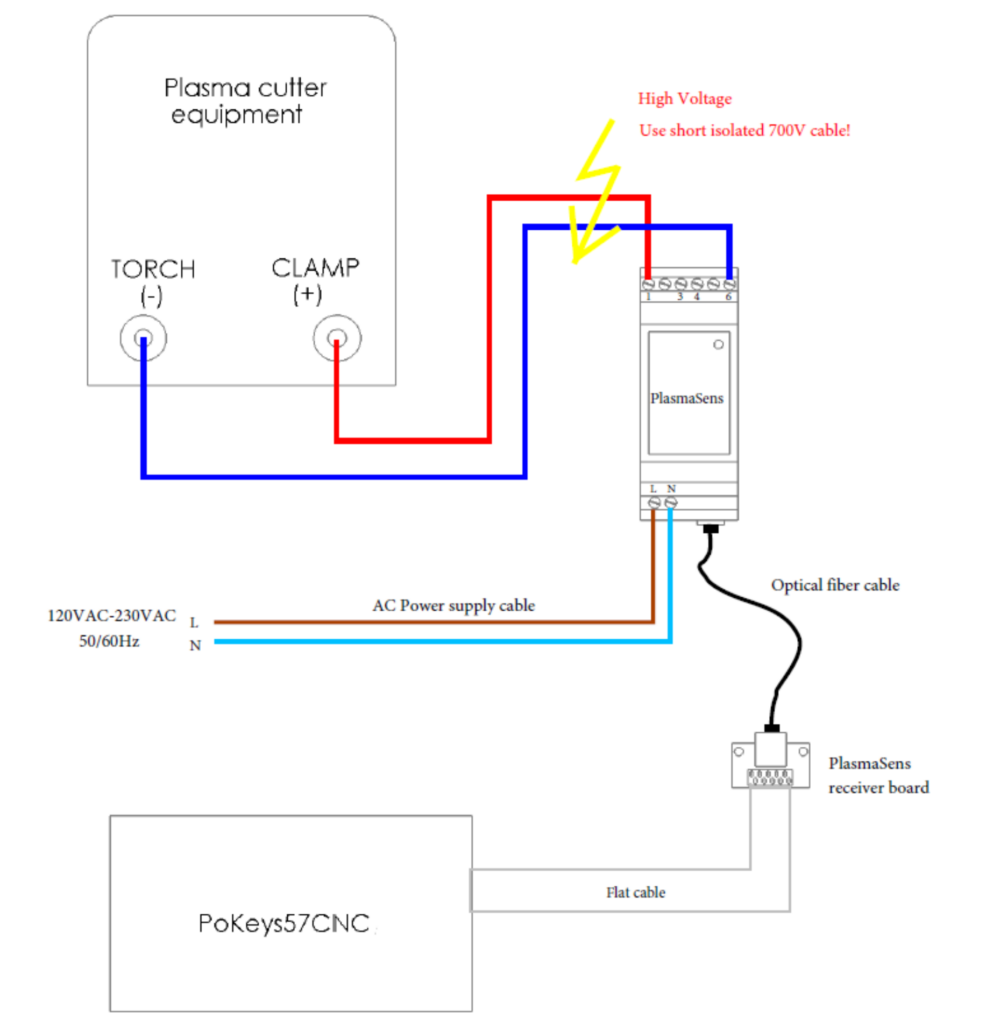

We offer different THC – torch height control options. PlasmaSens is most used with Mach and with our PoKeys57CNC motion controller. In this tutorial, we will test the functionality of the system. First, you need to connect the PlasmaSens to the PoKeys57CNC motion controller. They are connected via optical cable and PlasmaSensInterface board. It is essential to remove the cover from the optical cable before connecting it to the two devices.

PlasmaSens also has to be connected to the mains power (230V) in order to have the power supply for functioning but don’t plug it into the mains voltage yet. As a final step, there has to be voltage connected to the inner most terminals of the PlasmaSens voltage input. The inner terminals accept the voltage between 0-10V for which the regular battery is best fit for testing. Just be careful that you don’t mix up the + and – terminal of the battery.

If you want to connect the plasma cutter, you can also connect it via high voltage (outer most) terminals on the PlasmaSens.

Torch height control test – Testing the functionality

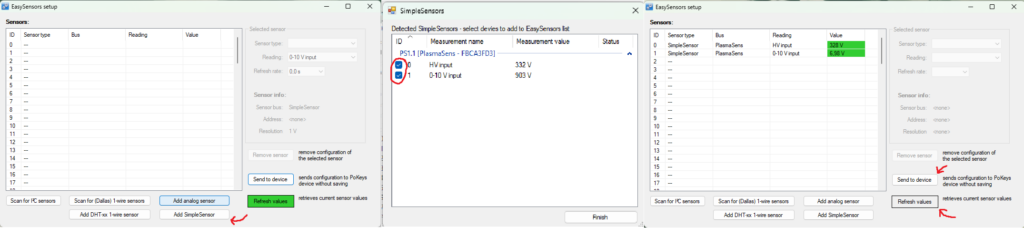

First step is to download the latest version of PoKeys software. Connect the PoKeys57CNC to computer via USB or Ethernet and open the application. Then update your PoKeys57CNC with the latest firmware as well. Then open the “EasySensor” tab under the “Peripherals“. Add SimpleSensor and mark both LV and HV inputs and click “Finish”. Then “Send to device” and “Refresh values” and the updated values should be present at each HV and LV input.

If you have plasma cutter connected you can make test cuts manually and observe the voltages on the EasySensor window. That should indicate that PlasmaSens unit is working as intended.

Plasma cutting aluminium – what you need to know

Can you cut aluminium with a plasma cutter? There are many misconceptions when it comes to this topic, however the bottom line is yes, a plasma cutter will cut aluminium. In fact, today’s plasma systems, especially Hypertherm’s newest X-Definition™ class plasma, are one of the best ways to cut aluminium. Though some people think laser is a better and more cost-effective method of cutting aluminium, the reality is quite the opposite. The reflective, soft, and thermally conductive nature of this metal makes the use of both fiber and CO2 lasers challenging and expensive. When using laser, cutting speeds are often slower and...

What is the Powermax SYNC plasma cutting system?

The Powermax SYNC® is a new air plasma platform from Hypertherm. There are three systems in all – the Powermax65 SYNC®, Powermax85 SYNC®, and Powermax105 SYNC®. The Powermax65 SYNC is designed for gouging and cutting up to 20 mm (3/4 inch), the Powermax85 SYNC is designed for gouging and cutting up to 25 mm (1 inch), and the Powermax105 SYNC is designed for gouging and cutting up to 32 mm (1 ¼ inches). Typical applications include drag cutting, bevel cutting, fine feature cutting, extended reach cutting, and gouging. Powermax SYNC makes plasma cutting easier Powermax SYNC plasma systems feature built-in intelligence and a revolutionary single-piece cartridge consumable, simplifying...

Invest in cut quality

There are many reasons why customers choose to invest in a Powermax® plasma cutter, but one of the most important is the consistent cut quality it delivers. Whether the cuts are made with a handheld plasma torch, a CNC machine torch, or a robotic torch, cut quality from a Powermax is noticeably better than competitive products, not just when the torch consumables or cartridge is new but even after hours of use. This consistent, high-cut quality difference tremendously impacts the reduction or elimination of secondary operations such as grinding, which in turn lowers the customer's cost of operation and increases their...

Plasma cutting stainless steel - common questions and considerations

Can you plasma cut stainless steel? Yes. The use of a plasma cutter is one of the best ways to cut stainless steel. In addition, plasma’s ability to cut a wide range of stainless steel thicknesses makes it the most versatile method. Plasma cutting stainless steel is also a cost-effective method, thanks to plasma’s lower capital and operating cost when compared to laser and waterjet and its ideal balance of cut speed and cut quality. What kind of cut quality should I expect when plasma cutting stainless steel? It is possible to produce plasma-cut stainless steel parts with excellent quality. Hypertherm’s X-Definition™ plasma process...